ENGINEER

TECHNOLOGY

GROUP

Baltimore Area

Council

The engineer is

someone who may be doing just about anything from working on a new chemical

process, to planning how to get water to your house. Point out to the Webelos in

your Den that an engineer is a planner who is found in many fields: civil

engineers - plan towns, electrical engineers - plan power plants and large scale

electrical wiring. chemical engineers, mechanical engineers; any field that

needs to have its work done for utmost efficiency and reliability.

Circle Ten

Council

Scientists who build machines are

called engineers. They do tests and experiments that help them to invent new

machines and make old ones work better. Without engineers we wouldn’t have

tools, engines, trucks, trains, clocks or can openers. Humans are the only

animals that invent and make machines. We use them to build skyscrapers, lift

heavy loads, and move faster than the speed of sound. Humans have even made

machines that can travel to the moon.

Den Activities

Baltimore Area

Council

Arrange for boys to visit an engineer or surveyor in

a municipal or county office. Plan for the boys to look through a surveyor’s

transit and “read a rod” or visit a construction site and see the plans, which

are being followed.

Make a block and tackle. Be

sure to explain its purpose - to lift weights easily. A single block and tackle

has an ideal mechanical advantage of two, which means that if there was no

friction, a one pound force can pull two pounds. A double block with one pound

pulling force could lift four pounds. As additional blocks are added, the

mechanical advantage is increased, but each additional pulley also decreases the

distance the load is moved. Friction is a factor affecting the lifting power.

Have the boys find pictures of different bridges and

bring them to a Den meeting. The differences in many kinds of bridges will

become apparent as the boys study them and construct models. The simplest ones

are plank, beam, pier, deck, truss, and arch types. The more complex kinds are

the bascule (the old castle drawbridge type). vertical lift, cantilever, and

pontoon. Many swinging bridges are in use today.

Discuss property lines. Have an expert show the boys how property lines are determined,

and how to measure one.

Discuss different types of engineers. If one of the dads is

an engineer, ask him to describe briefly to the boys what his duties are.

Surveying

Land

Baltimore Area

Council

Survey land, it could be yours

or a staked out section in a schoolyard or park with fixed points. To mark the

points, you can use a nail pushed through a rag.

To do this, you

will need a compass and a 100-foot tape measure. Put the compass on top of a 2 x

4 approximately three feet long. Start at one corner of the area to be surveyed.

Take a reading of your compass and measure the distance to the next point. Do

this all around the area that you have chosen to be surveyed - marking down your

distance and degree.

360 degrees North

40’ Points A to B

90 degrees East

100’ Points B to C

180 degrees South

40’ Points C to D

270 degrees West

100’ Points D to A

A surveyor’s

transit works much the same way. It gives the surveyor degrees in elevation as

well as the degrees horizontally.

Steam Electric

Power Plants

Baltimore Area

Council

They create steam

by heating water in a nuclear reactor or in a combustion chamber, where coal,

oil or gas is burned. The steam turns a turbine that runs a generator. The

generator has a rotating electromagnet called a rotor and a stationary part

called a stator. A separate generator called an exciter powers the rotor,

creating a magnetic field that produces an electric charge in the stator. The

charge is transmitted as electricity. A transformer boosts the voltage. Exhaust

steam passes cool water pipes in a condenser and turns back to water for

re-heating. The water that has absorbed the steam’s heat in the condenser is

piped to a cooling tower to be cooled.

Things To Make

Baltimore Area

Council

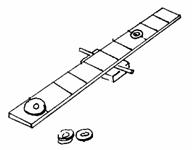

Balance

A balance is not

a weight scale, but is a device to measure an amount of one thing equally to

another (in weight), not to a scale.

Materials:

1” x 4” - 12”

long

1”x½” – 12” long

½” x 3” x 3”

plywood for base

Wire coat hanger

2 cup hooks

2½” long bolt

with washers and nut

(2) ½” x 3”

diameter plywood circles

6 lengths of 6”

chain

Instructions:

·

On the 1” x 1/2”, carefully measure and find the

centers for a hole in the middle, equal distance from both ends and from both

edges.

·

Drill it.

·

Put cup hooks in the board bottom - 1” from the

ends.

·

On the bottom, equal distance from both ends; drill

a hole big enough to put a piece of coat hanger through.

·

On the 1” x 4”, drill a hole 2” from the top and

equal distance from both sides on the 4” side of the board from top to center.

·

Attach the 1” x 4” to the 3” x 3” in the center of

the base.

·

Cut a straight section of coat hanger about 6 to 8

inches long and glue into the hole on the 1”x 1/2”.

·

Bolt the 1” x 1/2” to the 1” x 4” - You want enough

play so the 1” x 1/2” moves freely, but not sloppy.

·

On the 3” diameter circles, find 3 points equal

distance around the edge and tack a length of chain to each point, then attach

the three chains to the cup hooks.

·

If all works well, the coat hanger should lay on the

centerline of the 1” x 4”. If this doesn’t happen, weights (bent nails) can be

hooked over the lighter arm and moved back and forth until balance is gained.

Bridges

Baltimore Area

Council

The earliest

bridges were probably a log fallen across a stream. Someone probably learned

that several logs side by side made it wider and easier to cross. You could make

a longer bridge by putting logs or slabs of stone across stepping-stones over a

wider stream. These are the same principles that are used in many modern

bridges.

Make a plank

bridge out of a piece of poster board or a cereal box 10 inches long and 4

inches wide. Place it between two blocks or thick books. See how many toy cars

it will support. Now bend the sides up 1/2 inch from the sides like handrails.

See how many toy cars it will now support.

What you have

done is changed a plank bridge to a beam bridge. It acts like a much thicker

plank without the weight or expense of more material.

Beams are thick

at the center where more weight is supported and thinner near the ends where

there is less weight. The beams are usually made lighter by making them out of

lots of small triangles. The beams are started at the center and built out on

both sides equally to maintain balance like a seesaw.

Try this

experiment to see why triangles are used. Nail the ends of four scrap boards

together to form a frame. Use only one nail per corner. See how easily this four

sided structure collapses? This is how a bridge would act made from a shape

other than triangles. Now nail a board on a diagonal between two corners across

the frame to form two triangles. See how much stronger it is?

Arch bridges are

some of the longest lasting in the world. Some are over 1,500 years old! The

arch can be entirely over the roadway, entirely under the roadway, or in the

center. You can make a pretty good model of an arch bridge by using a hole saw,

like you would use to drill a hole for a door knob, and drilling holes in a

board. Cut this out with a cut through the center of the holes and you have the

two sides of an arch bridge. Place another board on top for the road the draw

and paint the stones on the side.

Bridge Activity

Baltimore Area

Council

Have boys build

two demonstration bridge side frames - one of rectangles and one of triangles.

Use stiff cardboard or thin wood and brass fasteners. Have them experiment to

see which type of bridge is stronger.

Ideas for

Engineer

Circle Ten

Council

Speakers – electrician, heavy

equipment operator, plumber, telephone lineman, sanitation worker, railroad

engineer, surveyor, city engineer, traffic planner, draftsman, architect.

Places to visit:

·

Visit the municipal offices of the city engineer or

surveyor. Look at a map of your town or city and try to find your house. Look

at some of the surveying equipment and learn some of the simple math

calculations.

·

Tour the city water works, sanitary facility or

recycling center. Ask about the current workload, and kinds of daily activities

that go on. How do they handle emergencies?

·

Visit an operational drawbridge, grain elevator,

ship or grain loading operation, or other large industrial operation involving

large cranes or other lifting equipment.

·

Visit a jeweler and look at various gems under the

microscope. How does the pattern affect the way a jewel is cut?

Den Activities:

·

Ask your local Boy Scout troop to give a

demonstration of some of the skills needed for the Pioneering Merit Badge. One

particular item of interest would be to see a rope monkey bridge being lashed

together.

·

Ask Webelos to look through books and magazines at

home and bring in pictures of bridges. Note the difference in construction.

Levers

Circle Ten

Council

A lever helps you to lift things

easily. A lever can be made by laying a plank over a wooden log or can with

both ends intact. Balance the plank so that there is a short end and a long

end. Place the short end under the object to be raised and push down on the

long end. Try raising some bricks. To experiment you can try to raise things

with the short end and you will find that it is more difficult or not possible

to raise the object. The longer end of the plank gives you the ability to

create more force and therefore raise weights easier.

Perhaps the simplest machine of all

for increasing force is the lever. A wheelbarrow is a king of the lever. Many

other types of complicated machines are really just collections of levers that

are put together to work in different ways.

Simple

Levers

Materials:

Length of

wood Glue

Small wooden

dowel Ruler

Stripes of colored

paper Pencil

Matchbox Weights (washers or coins)

How it works –

A simple lever is a straight rod that

rest on pivot or fulcrum. When you push one end of the rod down with an effort,

the other end goes up, lifting the load.

Try making this model seesaw and find

out for yourself how levers work.

Mark the length of wood with stripes

spaced about 1-inch apart.

Glue the dowel to the matchbox to make

a pivot.

Place the center of the length of wood

on the pivot so that the two ends balance.

Now try some experiments with the

weights.

Put a weight (the load) three marks

from the fulcrum.

Where must you place another weight

(the effort) to lift the load?

More load for less effort!

If the load is close to the fulcrum,

it’s easier to lift and you don’t need so much effort. You may have noticed

this if you’ve ever played on a seesaw – you can lift someone heavier than

yourself if they sit nearer to the middle than you do.

Try putting two weights (the load) two

marks away from the fulcrum of your seesaw. Where must you put a single weight

to lift the load?

Belt Drive

Merry-go-rounds, sewing machines,

record players, fishing reels, washing machines, and bicycles: these are just a

few of the many machines that turn, or rotate, as they work.

All the different rotating parts

inside a machine can be connected with a drive belt. As one part turns, it

drags the belt around with it, carrying its turning motion to the other parts of

the machine.

How it works – a drive belt

runs round a series of pulleys to carry the turning force from one place to

another. If the belt is going to work properly, there must be friction between

it and the pulleys, so that the belt does not slip. If the belt is too slack it

will not grip. If it is too tight, it might break or twist the pulleys out of

line.

Whirling

Acrobats

Circle Ten

Council

Materials:

Sandpaper Wooden board

Glue

Cardboard

Velcro –

self-adhesive Ribbon

Wooden

dowel Empty thread spools

Directions:

1.

Cut sandpaper into strips, and glue a strip

around each of the thread spools. The rough surface of the sandpaper is needed

to make some friction between the reels and the belt. This way, the belt will

not slip.

2.

Draw both the front and the back of each figure

on a piece of cardboard as shown, leaving a space between front and back to make

a base.

3.

Cut out the figures.

4.

Then fold and glue them so that they stand up.

5.

Glue a figure onto each spool.

6.

Cut the wooden dowel into a number of shorter

dowel pegs.

7.

Smooth the ends of the pegs with sandpaper.

8.

Drill holes into the baseboard. They should be

just big enough for the dowel pegs to fit snugly into them.

9.

Put the pegs into the holes,

10.

Put a thread spool onto each peg.

11.

Check that every reel can turn freely on its

peg.

12.

Push a short piece of dowel into the top of one

thread spool and glue the spool to the bottom peg. Put this spool on peg #5.

This is the drive belt handle. You will use it to turn the drive belt.

13.

Stretch a length of ribbon around the spools so

that it touches them all. Use a piece of Velcro to join the ends of the

ribbon. Then you can adjust it so that it is not too tight and not too slack,

and the figures will turn more smoothly.

Changing

Direction

Both of the figures will turn in the

same direction as the drive belt handle is turned when placed on any combination

of spools 1, 2, and 6. Both of the figures will turn in the opposite direction

of the drive belt handle when placed on spools 3 and 4. Notice what happens

when one figure is on spools 1,2, or 6 and the other is on spool 3 or 4.

Changing

Speed –

If all the thread spools have the same

diameter, they all rotate at the same speed. But if you use different-sized

spools, they turn at different speeds. To turn a big spool, the belt has to

move farther than it does to turn a smaller one, and so the big spool turns

around more slowly.

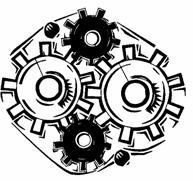

Gears

You’ll find gears inside nearly every

machine that turns. Clocks, watches and bicycles all use them. Just like belt

drive, the gears connect all of the rotating parts, but gears last longer than

belts and are more precise. If you’ve ever ridden a mountain bike, you’ll know

that gears are a good way of changing speed.

Cardboard

Gears:

Circle Ten

Council

This is a great section!! Having been a Machine

Design major for my BS and MS ME, I can get into gears!! CD

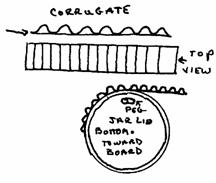

How it works – the best way to

find out how gears work is to make some of you own to experiment with. Each of

these homemade gears is made from a jar lid with a strip of corrugated

cardboard, stuck around the rim. The corrugations face put to make the gear

teeth.

Materials:

Strips of corrugated cardboard (1/2”

wide) with corrugations exposed

Jar lids and bottle tops of different

sizes

Pin board and push pins

Short dowel peg

Glue and paper

Directions:

1.

Bend a strip of cardboard around the rim of a

jar lid. Try to stretch it into place so that there is a whole number of teeth

evenly spaced around the lid. Cut the strip carefully to length and then glue

it in place.

2.

Make a small hole in the middle of the gear and

pin it to the board so that it spins freely.

3.

Make a selection of different-sized gears to add

to the board. Glue a dowel peg to one of the gears to make a crank handle.

4.

To make the gears work you must place them so

the teeth mesh. When you turn one gear its teeth will push on its neighbor’s

teeth and make them turn in the opposite direction.

Gear Experiments

Connect a series of gears like the one

shown.

If you turn the big gear,

*

What happens to the two smaller ones?

*

Which way do they go around?

*

Which does a complete turn first?

Now try turning the small gear –

*

Do the bigger gears turn more quickly or more

slowly?

Count the number of teeth on each

gear.

*

If you turned a gear with 20 teeth around once, how

many times would it turn a gear with 10 teeth?

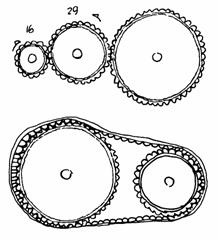

Drive Chains –

Circle Ten

Council

In some

machines, gears called sprockets are connected by a drive-chain. A bicycle

chain connects a sprocket on the pedals to another one on the back wheel. The

chain transfers the movement from the pedals to the wheels.

Make a

model chain from a long strip of corrugated cardboard with the ends taped

together. Loop it around two different sized gears and work out how far the

small gear moves then you turn the larger one.

Hollow

Tubes

Circle Ten

Council

To demonstrate the strength of hollow

tubes, try laying a brick on a Styrofoam cup lying on its side. Place another

cup on its rim and add bricks (2 to 3) until it crushed. Glue four cups

together rim to rim and bottom to bottom with white glue and allow glue to dry.

Place bricks (usually 4) on top until the structure crushes. Demonstration

shows why engineers use columns in structures and bridges.

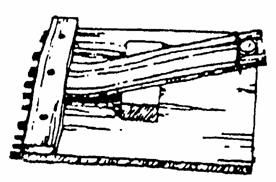

Springs –

Springs store energy when compressed,

which is released when the spring is released. Catapults are a form of springs.

Catapult

Circle Ten

Council

Materials:

Wood

scraps Ruler or yardstick

It can be any dimension. Use a ruler or

yardstick or any flexible wood for deadman arm. Leave spring bar loose so you

can test catapult with various leverages.

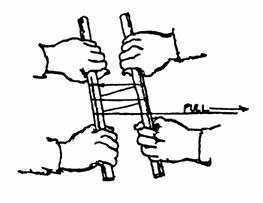

Block and Tackle

Circle Ten

Council

Materials:

2 Dowel rods (1” or

larger) Sash cord or clothesline

Tie the

cord to one dowel and make three wraps around both dowels. Have two big Webelos

Scouts try to pull the dowels apart while a smaller boy pulls the loose end of

the cord. He will be able to draw the larger boys together, no matter how hard

they pull. The block and tackle does not create more power; it merely trades

distance for force.

Block and Tackle Power (Part 2)

Baltimore Area

Council

To show how a

simple block and tackle increases pulling power, try this demonstration. You

need two dowels of broomstick diameter and a length of clothesline. Tie the line

to one of the sticks. Wrap it around both sticks two or three times. Have two of

your larger Webelos Scouts grasp the sticks. Have the smallest boy pull on the

line. He will be able to pull the two sticks together no matter how hard the

bigger boys try to hold back.