CHARCOAL

POWERED WATER HEATER

By Anthony Ferraro

Woodbadge

C-36-00

STATEMENT OF PROBLEM

During campouts two burner stoves are typically used to

prepare meals. Both burners are usually

required to prepare meals, which means that water is not being heated for

cleaning dishes afterwards. It takes a

long time to heat up enough water to provide wash, rinse and sanitation

containers. By this time the Troop is

planning to move on to the next activity

DESIGN CRITERIA

One of the primary goals was to build something that can be

easily reproduced with “off the shelf parts.”

All the parts are suitable for domestic water use, in case the water is

consumed. The challenge in building this device was how efficient can I make the

heat transfer portion so that not much fuel (charcoal) would be required. Another challenge was to retain the heat

once the water was heated. It was also

meant to be an educational tool for the Scouts. This device makes a good topic of discussion for the Energy merit

badge. Later in this report I will review the calculations.

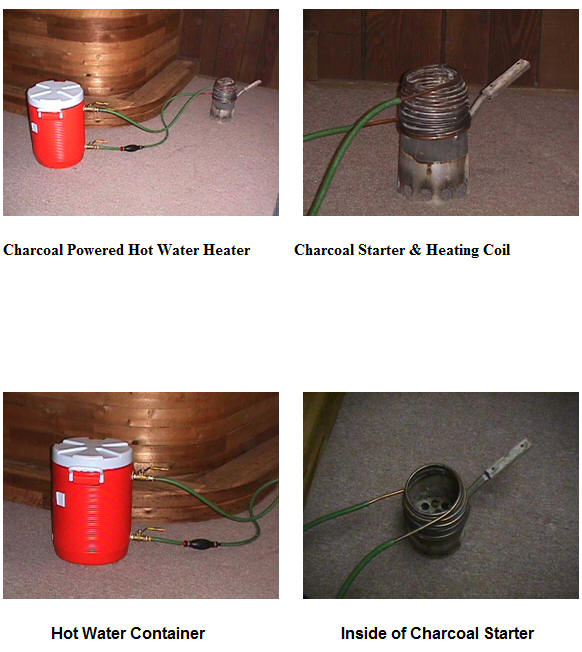

THE PARTS & HOW IT OPERATES

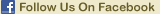

A 5 gallon water container satisfied several

requirements. It was large enough, it

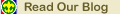

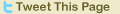

was insulated and has a spout at the bottom to easily draw water. A charcoal fire starter was the key to relatively

efficient heat transfer. The device

operates by placing some newspaper in the base of the unit and the charcoal is

loaded into the top. When the newspaper

is lit a draft is created similar to the stack effect of a chimney. This constant air flow gets the charcoal

glowing much faster than if it were laying in a flat pan. Heat is radiated out where the copper pipe

is. The fifteen feet of copper pipe is 3/8” thin wall, this made it easy to

bend into a tight radius. Next some

flexible tubing was needed to separate the water container from the heat

source. Standard garden hose would not work here because of the high

temperatures. A high temperature 3/8”

hydraulic hose was purchased for the job.

Finally brass bulkhead fittings and ball valves were used for the supply

and return lines. The ball valves are

closed when you want to fill the container separate from the heat exchanger and

once the water is heated. The hoses slip on and off the copper pipe.

When water is heated in a closed vessel a process called

convection occurs. Simply stated warm water rises to the top since it is less

dense than the cold water. This process is used in this device, the supply hose

(bottom of the container) is connected to the bottom of the heat exchanger and

the return hose (top of the container) is connected to the top of the heat

exchanger. The container needs to be filled to the top for the water flow to

begin. Since there is 21 feet of pipe ion this device, some resistance to flow

was unavoidable. To overcome this

resistance a marine primer pump was added.

The pump has a check valve inside it so flow would go in one direction

when squeezed. In testing it took

approximately 45 minutes to raise 5 gallons of water from 60 degrees to 120

degrees.

THE CALCULATIONS

This is why the water heater works. Bear with me as I go through this. A gallon of water weighs 8.34 lbs. A British

Thermal Unit (BTU) is the amount of energy required to raise 1 pound of water 1

degree Fahrenheit. Below is a calculation to determine the amount of heat

needed to heat 5 gallons of water from 60F to 120F.

8.34

lbs/gal.

x 5.0 gallons

41.7 pounds

x 60 degrees F

2,502 BTU’s

x 2.5 assume a 40%

efficient heat exchanger

6,255

BTU’s required

I e-mailed the good people at Kingsford to get a vital piece

of information, the BTU content of charcoal. They sent an answer the next day,

it was 9,700 BTU/pound. Using this

information we can see that just 1 pound of charcoal is needed to operate the heat

exchanger. This equals about 10

briquettes, which easily fits into the heat exchanger.

CONCLUTIONS

I would like to thank Siemens Building Technologies for the

donation of the copper pipe. I also got some good feedback from the students at

Scoutmastership Fundamentals. They

suggested adding the squeeze bulb and adding some type of baffle on the top of

the heat exchanger to force more heat to in between the coils. I will give this a try on the next

campout. During field testing some

interesting things came to light. Do

not close the valves while the coals are still hot, water turns to steam, steam

builds up pressure to the point where one of the hoses blows off, creating a

safety hazard. Once you are done

heating water, disconnect the hoses from the heat exchanger so they can

drain. On one campout the temperature

overnight dropped to 12F, we were able to clear the ice from the hoses but

could not de-ice the squeeze pump. On

that cold overnight the heat retention of the container was truly impressive. The water was heated to roughly 120F at

dinner time, not all the water was used, with the cover on the remaining water

was still 90F the next morning. Quick

disconnects would have been nice to have in place of the ball valves but they

were a bit too expensive. The total

cost for the materials was around $50.00. I already had the charcoal starter

and the copper pipe was donated. This

device cannot be justified solely on the savings of Colman fuel not used by the

stove to previously heat the water. As

I mentioned earlier its main purpose is to encourage Scouts to practice good

sanitary habits. If they also learn and

understand the engineering side to the device that is a bonus.

If you are interested in building this device, feel free to

call me at 513-755-7627 or e-mail at kathytony5@netzero.net. I am also interested in any improvements or

ideas you may have to the existing design.